DIRECT INFLUENCE OF THE ELECTRON BEAM ON THE SURFACE OF THE MATERIAL (DIRECT MODIFICATION)

When exposed to intense pulsed electron beams, the material layer thickness that is equivalent to capture length in the material (from 10 to 100 microns), is very quickly heated up to phase transition temperature.

At the end of beam pulse the heated layer is rapidly cooled by the process of thermal conductivity in the depth of the material. As a result, the surface layer properties are changing:

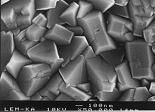

• changing of the microstructure - grain size decreases from hundreds of microns to fractions of a micron, it is possible a transition to amorphous state, and a formation of nanostructures;

• changing of the phase composition, with the possible occurrence of metastable phases and compounds which can not be formed when the usual methods of heat treatment are applied;

• phase composition is being homogenized, for example, carbides in steels are being crushed and uniformly distributed.

Practical consequences of these changes are the enhancement of hardness, corrosion resistance and wear resistance of the materials surface, reducing the coefficient of friction, increasing the dynamic strength of products.

CHANGING OF THE SURFACE LAYER MICROSTRUCTURE

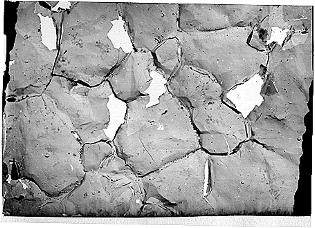

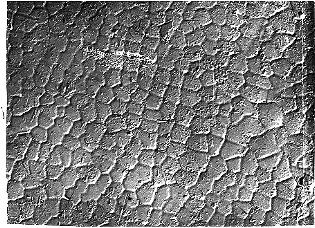

Stainless steel 12Х18Н10Т

|

|

| Microgeometry of the surface before the treatment by an electron beam (left) and after treatment (right) | |

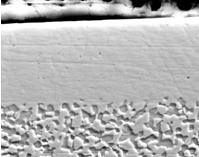

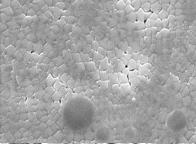

Protective coating NiCoCrAlY

|

|

| Microgeometry of the cross section of the coating after electron beam treatmentлектронным пучком | Microgeometry of the surface of the coating after electron beam treatment |

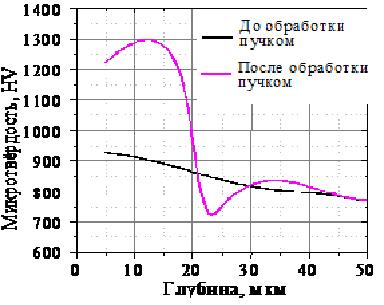

IMPROVING OF MICROHARDNESS IN AUTOMOTIVE INDUSTRY

| Steel grade | The energy of the electrons, keV | The pulse duration, microsec. | The thickness of the layer, microns | Hardness before treatment, kg/mm2 | Hardness after treatment, kg/mm2 |

| 40ХН2МА | 150 | 20 | 25 | 170 | 350 |

| 50Х20Н4АГ9 | 150 | 20 | 40 | 250 | 800 |

| 40Х9С2 | 100 | 8 | 18 | 300 | 700 |

| 40Х9С2 | 140 | 14 | 12 | 300 | 500 |

| 08КП | 180 | 6 | 22 | 200 | 1100 |

| 08КП | 150 | 20 | 50 | 200 | 700 |

| Ст6СП | 60 | 35 | 12 | 250 | 700 |

| Ст6СП | 180 | 8 | 25 | 250 | 550 |

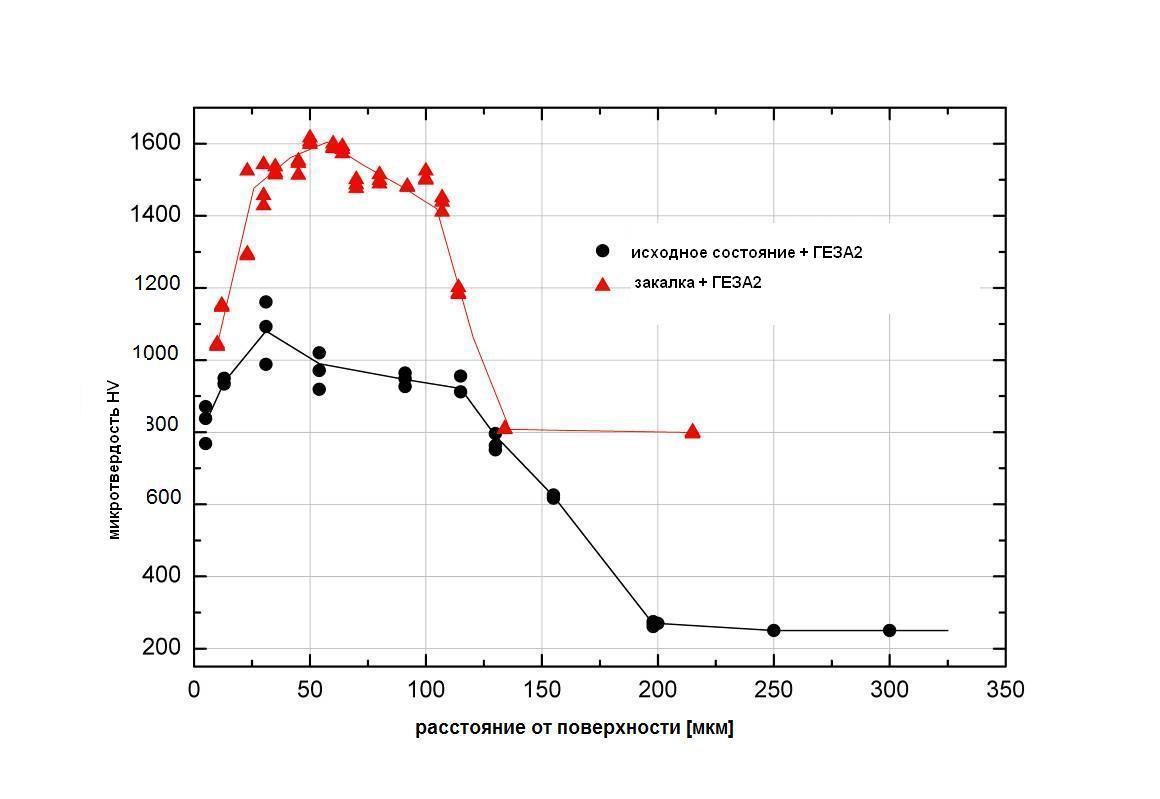

|

IMPROVING OF WEAR RESISTANCE OF A MACHINE ENGINES’ DETAILS

|

Details wear (mass loss) after engine test (18 runs, 2 hours per each run)

| Detail | Traditional technology of hardening, mg | Additional beam treatment | Improvement coefficient of wear resistance |

| Follower | 3,79 | 0,87 | 4,3 |

| Tappet | 2,04 | 0,88 | 2,3 |

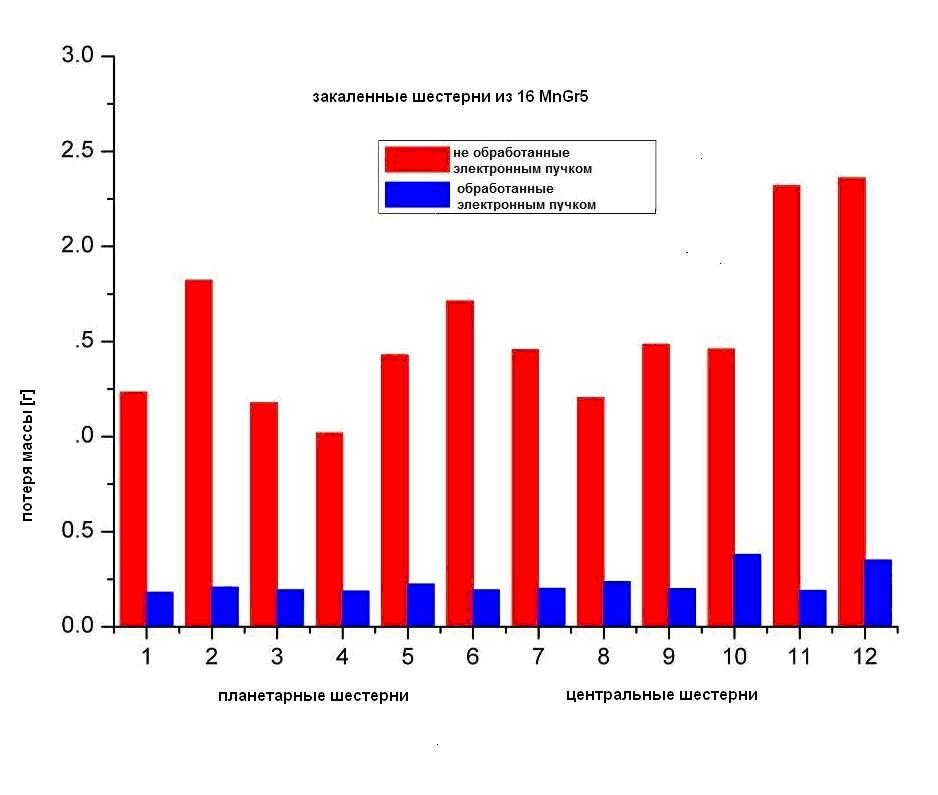

The wear resistance of gears treated with electron beam and without electron beam treatment. Improvement after electron beam treatment from 5 to 10 times.

|

MODIFICATION OF OXIDE LAYER MICROSTRUCTURE ON THE SURFACE OF THE PROTECTIVE COATING

Pulsed electron-beam treatment dramatically reduces the initial rate of protective coating oxidation that decreases the thickness of the oxide layer by 2-3 times. The difference between oxide layer growth rate on the polished surface and on the beam treated surface of the protective coating depend on different microstructure of the oxide layer.

|

|

| The microstructure of the oxide layer on the surface of protective coating MeNiCrAlY after polishing (left) and after pulsed electron beam treatment (right). Tests duration - 200 hours at 950C. | |