PULSED ELECTRON ACCELERATORS FOR MODIFICATION OF MATERIALS AND PRODUCTS

In many countries, beam technologies of materials modification are being developed and implemented in the industrial production. These technologies help to achieve the increasing of wear resistance, corrosion resistance, the dynamic strength of the products, polishing the surface, reducing the coefficient of friction, the removal of waste coatings. Interest in these technologies is due to the fact that their application in industry instead of the traditional methods (heat treatment in furnaces, quenching in acid and salt solutions, galvanic coating) allows to save energy, improve efficiency, reduce or eliminate environmentally harmful effects of production. In some cases, beam technology allows to obtain such structural-phase state of materials that can not be realized in any other ways.

For many years Efremov Institute designs, creates and implement electron-beam facilities, which can be used to modify properties of materials in order to improve the application requirements of various products. / RF Patent ¹2395866 “The source of pulsed electron beams (options)” Germany Patent DE 19541510 C2 «Gepulste Elektronenstrahlquelle und deren Verwendung»/.

To develop and implement technologies of modification of a materials’ surface properties there had been designed and manufactured GEZA-series accelerators:

| Technical characteristics | Geza-1 | Geza-2 | Geza-4 | Geza-5 |

| The energy of the electrons, keV | 50-150 | 200-500 | 100-120 | 100-120 |

| pulse current, A | 1000 | 500 | 1000 | 700 |

| The maximum area of the beam on the sample, cm2 | 80 | 50 | 100 | 80 |

| The pulse duration, microsec | 5-50 | 5-250 | 5-50 | 5-40 |

| The maximum energy density per pulse, J/cm2 | 100 | 500 | 50 | 50 |

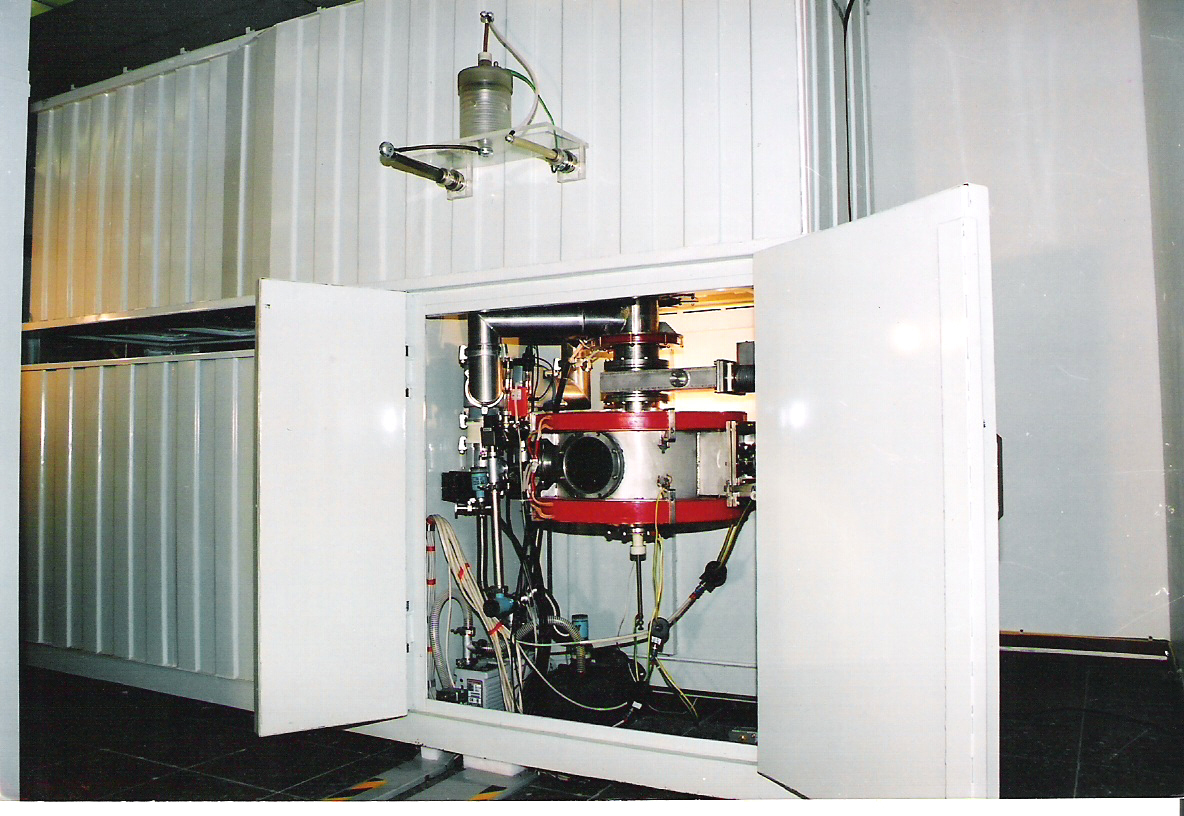

The prototype of the electron-beam unit for surface modification of the blades of gas turbine engines (Geza-5).

Modification of the surface properties of materials is being carried out in two ways:

- direct influence of the electron beam on the surface of the material (direct modification),

When exposed to intense pulsed electron beams, the material layer thickness that is equivalent to capture length in the material (from 10 to 100 microns), is very quickly heated up to phase transition temperature.

At the end of beam pulse the heated layer is rapidly cooled by the process of thermal conductivity in the depth of the material. As a result, the surface layer properties are changing:

• changing of the microstructure - grain size decreases from hundreds of microns to fractions of a micron, it is possible a transition to amorphous state, and a formation of nanostructures;

• changing of the phase composition, with the possible occurrence of metastable phases and compounds which can not be formed when the usual methods of heat treatment are applied;

• phase composition is being homogenized, for example, carbides in steels are being crushed and uniformly distributed.

Practical consequences of these changes are the enhancement of hardness, corrosion resistance and wear resistance of the materials surface, reducing the coefficient of friction, increasing the dynamic strength of products.

|

|

| Geza-1 | Geza-2 |

Surface properties of materials are being modified in two ways: