ARC SOURCES

Arc plasma sources are efficient in depositing various coatings (anti-corrosive, wear-resistant, heat-resistant, anti-friction, protective, anti-emission, biologically compatible, decorative, etc.).

|

|

|

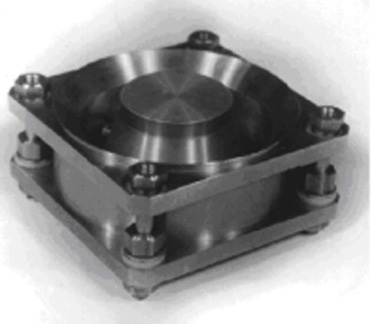

| Arc source of the metallic plasma | Arc source of the metallic plasma with arc magnetic confinement on the cathode end | Multi-component arc source ofпїЅthe metallic plasma |

|

|

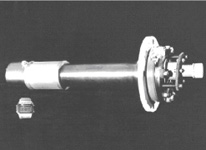

| Arc source of the metallic plasma | Arc source of boron plasma (with boron cathode) |

| Arc source of the metallic plasma | without arc control | with magnetic arc control |

| Operating current, A | 70 -300 | 25-300 |

| Operating voltage, V | 15 -30 | 20-40 |

| Evaporation rate of cathode material, mg/s | 2 -20 | 0,5-20 |

| Cathode material reserve, kg | 2 -8 | 0,1-3 |

| These coatings provide the following properties: | Arc sources are used for deposition of various coatings |

| wear-resistant | metal |

| anti-corrosive | metal nitride |

| heat-resistant | metal carbide |

| protective | metal oxide |

| anti-emission | semi-conducting structures |

| decorative | diamond-like structures |

Publications:

1. D.A. Karpov, Plasma technologies for coating deposition, Novye Promyshlennye Tekhnologii, 2003, issue 1, pp.38-41 (in Russian).

2. D.A. Karpov, Cathodic arc sources and macroparticle filtering, Surface and Coatings Technology, 96 (1997) 22-33.

Deliveries arc sources:

| Delivery year | Customer | Country |

| 1989 | Central Institute of Physical Investigations | Hungary |

| 1990 | Central Institute of Electronic Physics | Germany |

| 1992 | Ioffe Physical Technical Institute | Russia |

| 1992 | Vacuum Technique Dresden | Germany |

| 1994 | Svetlana Industrial Association | Russia |

| 1994, 1999 | Forschungszentrum Julich | Germany |

| 1995-1999 | ISM Technology Inc. | USA |

| 1997 | Forschungszentrum Rossendorf | Germany |

| 1999 | Multi-Arc Ltd. | UK |

| 2004 | Chinese Precision Machinery Import and Export Corporation | China |

| 2006-2008 | NanoShield Co., Ltd. | Thailand |