MHD-PUMPS_MHD-THROTTLES

Various types of electromagnetic pumps (EMP) have been designed and manufactured in NIIEFA to pump liquid metals (sodium, potassium, lithium, etc.) with the flow rate of 1 l/s to 4000 m3/h at the pressure of 0.15 to 2 MPa. Various types of MHD throttles to control flow rate of liquid metal and other electrically conducting flows were designed and manufactured. This equipment efficiency varies from several liters per second to tens of thousand of cubic meters per hour at 0.01-5 MPa operating pressure. The liquid metal temperature is 20 to 550oC. The EMP and MHD throttles are used in nuclear energetics, metallurgy, chemical industry, in energy conversion systems of space air crafts. NIIEFA is equipped with the test facilities for EMP and MHD throttles testing and for studying MHD flows and heat exchanging of liquid metal systems of the ITER test fusion reactor. The facilities are having eight 0.01-0.5 m3 liquid metal loops made of stainless steel and filled with sodium or sodium with potassium alloy at up to 600oC. Accumulating tanks for sodium and sodium plus potassium alloy are 2 m3 and 1.2 m3 respectively.

|

|

|

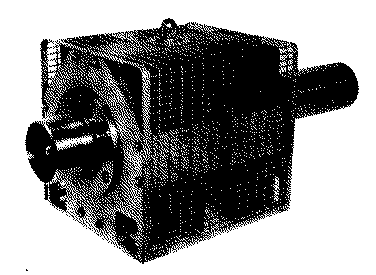

| Stand for liquid metal systems study. | Pump CLIN-3/3500. | Throttle MDC-4/230. |

| MHD-PUMPS_MHD-THROTTLES | ||

Magnetohydrodynamic valves

Magnetohydrodynamic (MHD) d.c. valves with cylindrical and helical channels are intended to control flow rate of liquid metals from thousand fractions to tens of thousands of cubic meters per hour at a pressure of 0.01-5.0 MPa.

МHD valves are the novel type of the MHD machines offering essential advantages over the known mechanical control valves:

- hydraulic resistance coefficient in the valve is less by a factor of 10-20 than that of a mechanical valve;

- high stability of characteristics and fast response;

- continuous remote and precision control over flow rate

Applications:

- in liquid-metal loops of nuclear power plants with fast neutron reactors;

- in chemical industry;

- in metallurgy;

- in various technological and experimental facilities.

|

|

| МHD valve of МДЦ-3/30 type. | МHD valve of МДЦ-3/20 type. |

| Main technical characteristics | Numerical values | Numerical values | Numerical values | Numerical values | Numerical values | Numerical values |

| Characteristics: | MHD-3/20 | MHD-5/8 | MHD-10/700 | MHD-0.8/1100 | MHD-3/30 | MHD-3/50 |

| Working medium | Sodium | Sodium | Sodium | Sodium | Sodium-potassium alloy (78 % porassium) | Sodium-potassium alloy (78 % porassium) |

| Working mixture flow rate Qн, м3/h | 20 | 8 | 700 | 1138 | 30 | 50 |

| Pressure drop Pн,, Pa | 3х105 | 5х105 | 10х105 | 0,8х105 | 3х105 | 3х105 |

| Hydraulic pressure drop, Pa | 0,016х105 | 0,3х105 | 0,8х105 | 0,2х105 | 0,4х105 | 0,2х105 |

| Current, A | 5 | 6,5 | 8 | 10 | 4 | 4 |

| Valve weight, kg | 190 | 55 | 310 | 860 | 60 | 60 |

| Position | Arbitrary | Arbitrary | Arbitrary | Vertical | Arbitrary | Arbitrary |

| Input and output pipe dimension (diameter x wall thickness), mm | 108х5 | 46х3 | 219х12 | 325х12 | 70х2,5 | 70х2,5 |

| Maximum temperature of liquid metal, °C | 350 | 350 | 350 | 400 | 150 | 150 |

Note:

All types of valves are naturally cooled; excitation coil supply voltage is 110 V; pressure drop at the arbitrary flow rate Q<Qн, is assessed by the expression Р=Рн . Q/Qн.

The MHD valves developed at the STC SINTEZ work in the nuclear reactors and experimental facilities at IPPE Obninsk; SRIIAR, Dimitrovgrad; SRC Kurchatov Institute, Moscow; OKB FAKEL, Kaliningrad.