HIGH-TEMPERATURE VACUUM SOLDERING AND THERMAL TREATMENT FACILITY

ќборудование Ц 4 современных вакуумных печи различного профил€ с автоматическим управлением на базе PLC.

|

| Manufacturing multiprofile vacuum furnace УSCHMETZ E 210/1 H 60 x 100 x 60Ф |

Main characteristics:

- Size of operating area 60x100x60 cm

- Heater type is Ц resistive, molybdenum

- Maximum temperature 13500—

- Vacuum up to 10-4 Pa

Features:

- Batch forced cooling function through nitrogen circulation or through inert gas pressure of 10 bar (absolute).

- Capability of gas puffing or flowing

|

| Manufacturing multiprofile vacuum furnace У“-ћ Super Series 12/24-14MD VIeФ |

Main characteristics:

- Size of operating area 30x60x30 cm

- Heater type is Ц resistive, molybdenum

- Maximum temperature 14000—

- Vacuum up to 10-4 Pa

Features:

- Batch forced cooling function through nitrogen circulation or through inert gas pressure of 2 bar (absolute)

- Capability of gas puffing or flowing

|

| Laboratory high-temperature vacuum furnace УOXY-GON EC600Ф |

Main characteristics:

- Size of operating area: diameter- 25, height - 50 cm

- Heater type is Ц resistive, graphite

- Maximum temperature 25000—

- Vacuum up to 10-4 ѕа

Features:

- Retort Type Furnace

- Capability of gas puffing or flowing

|

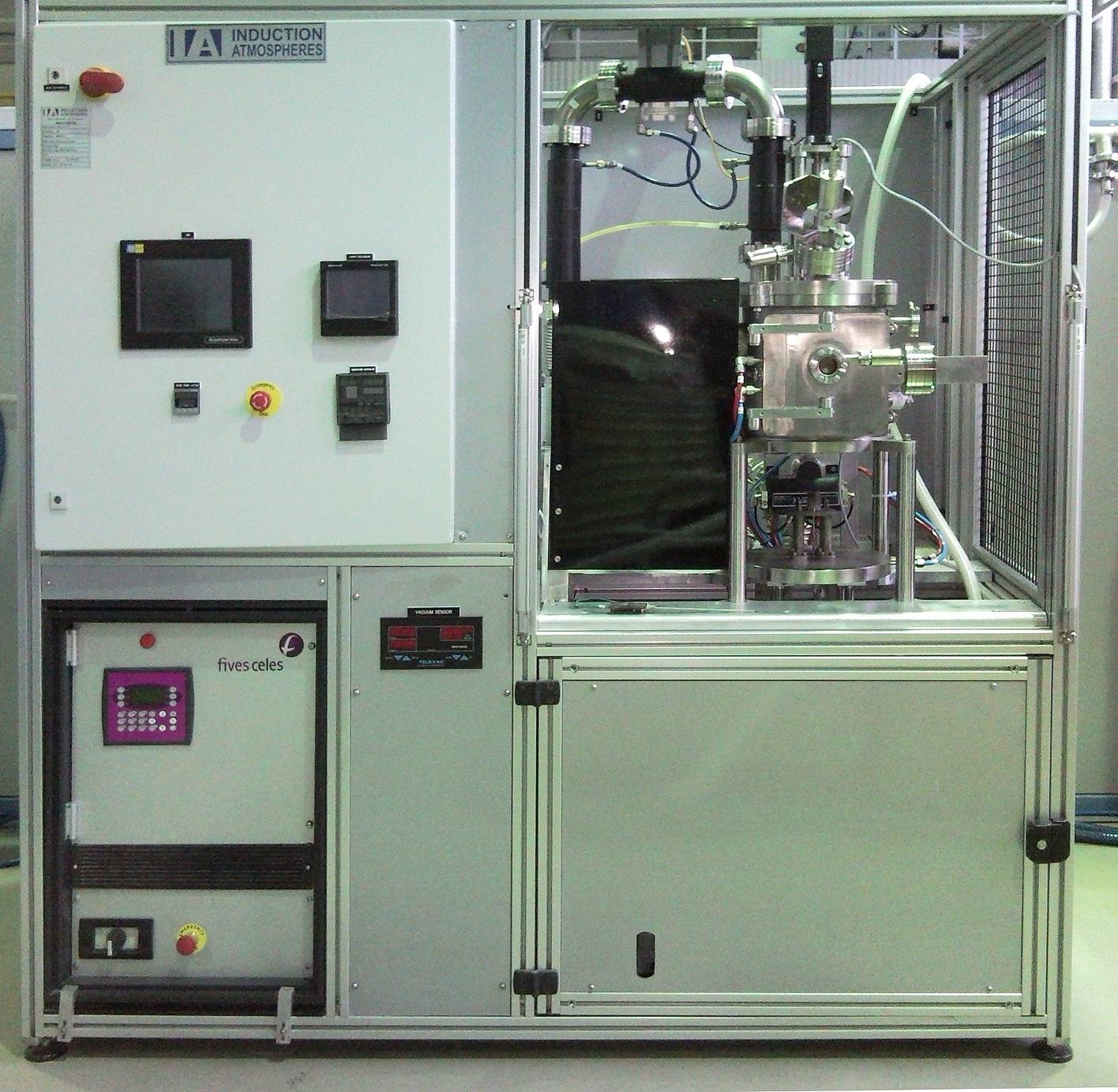

| Laboratory induction furnace vacuum furnace УVIF 25/100Ф |

Main characteristics:

- Size of operating area: diameter- 6,3, height Ц 10,7 cm

- Heater type is Ц inductive

- Maximum temperature 15300—

- Vacuum up to 10-4 ѕа

Features:

- Batch fast heating

- Changeable inductors

- Batch forced cooling function through inert gas pressure of 1,5 bar (absolute).

PROCESSES:

- annealing

- tempering

- tempering

- scale-free hardening

- high-temperature vacuum soldering

- artificial deterioration (tempering)

- complex multistage thermal treatment

|

| Furnace soldering of the ITER fusion-type reactor element in the furnace У“-ћ Super Series 12/24-14MD VIeФ |