EFASCAN

CUSTOMS INSPECTION COMPLEXES FOR CONTROL OF LARGE-SCALE CARGOS

|

As a result of increasing volume of world trade the necessity of fast and easy transportation of goods by auto, sea and air transport puts tremendous pressure on customs services all around the world. Because of a great deal of commercial goods is stacked and transported in large-scale containers, the traditional inspection methods meet lots of physical and financial handicaps, especially time needed for inspection. To get rid of these difficulties Inspection Complexes (EFASCAN, EFASCAN-2 and EFASCAN-3) for cargo control was developed.

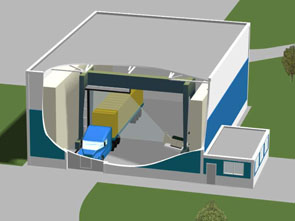

The purpose of Inspection Complexes is examination of vehicles and large-scale containers without their opening to expose contraband goods. Radioscopic examination of objects is performed by means of fan X-ray beam, which is generated by linear electron accelerator. Penetrated through the object radiation is registered by detector line. Signals from the detectors are preliminary processed and transmitted to the workstations of the customs officers.

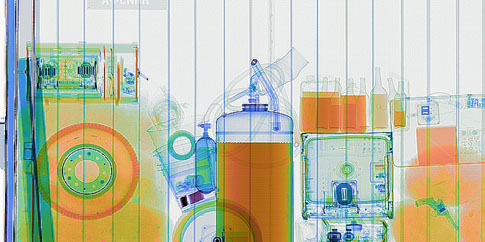

Special software processes data from the detector line and visualizes high-resolution image of the inspected object on screen of the workstation in the real time mode.

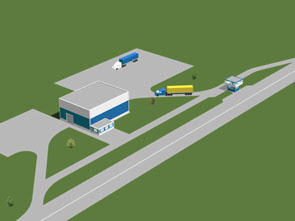

EFASCAN is intended for application at customs security checkpoints: at railway stations, airports and seaports. The inspection takes place in a special radiation shielded hall. During the scanning the transportation system moves the examined object across X-ray beam with 0.4 m/s constant speed.

|

|

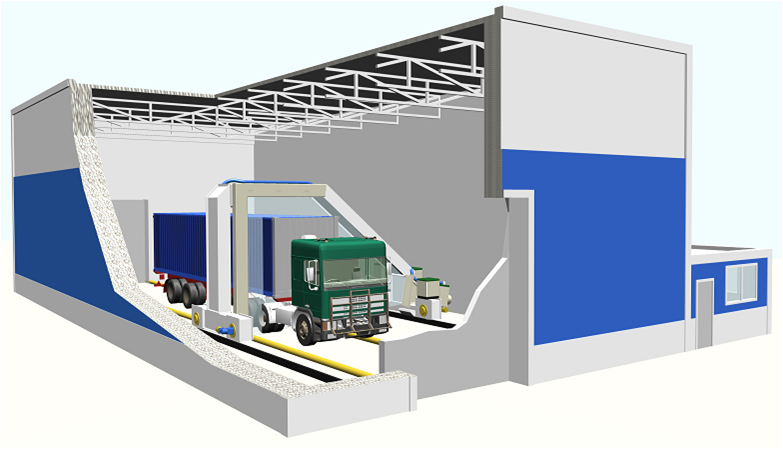

| The layout of the EFASCAN complex building (variant for containers) | Radioscopic examination of mini-bus |

|

|

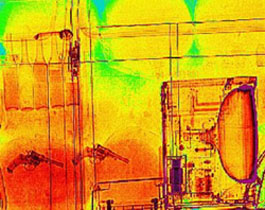

| Mini-bus image on a screen of inspector's workstation | Zoomed pseudo colored fragment of mini-bus image |

|

|

| Fragment of cargo container image in pseudo color. Four cartridges and two packings with narcotics are hidden inside the truck wheel. On the right side a defectometer for measurements of spatial and density resolution is placed. | Image of testing case for measurements of spatial and density resolution. Spatial reconstruction without temporal averaging was applied (result of testing offered by representatives of Russian North-West Customs Authority, St. Petersburg). |

|

|

| Motorcycle image on a screen of inspector's workstation | Image of 1/5 m cylindrical container filled with sand before and after processing by special mathematical function realized in applied software |

The purpose of EFASCAN-2 is examination of motor vehicles at roads with high cargo traffic. Linac, detector line and X-ray beam collimation system are installed on special transportation system ensuring their travel relative to an object under inspection.

|

|

| General view of the EFASCAN-2 complex building | The layout of EFASCAN-2 complex |

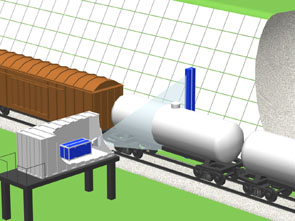

EFASCAN-3 is intended for freight trains inspection at railway stations. During the scanning the freight train moves across X-ray beam with 5 m/s (18 km/h) constant speed.

|

| EFASCAN-3 - Inspection of freight train |

EFASCAN-2 and EFASCAN-3 complexes can be delivered in modifications when the attending personnel is protected against ionizing radiation with local shields and due to remote control of the accelerator.

| Major technical specifications of EFASCAN and EFASCAN-2 | ||

| Parametars | EFASCAN | EFASCAN-2 |

| X-ray source energy, MeV | 9 | 6 |

| Radiation penetration depth in steel equivalent, mm | 380 | 320 |

| Spatial resolution, mm | 3 | 3 |

| Spatial resolution for high contrast objects, mm | 1 | 1 |

| Density resolution, % | 1 | 1 |

| Throughput (2.5 x 2.5 x 12 m), containers per hour | 25 | 25 |

| Major technical specifications of EFASCAN-3 | |

| X-ray source energy, MeV | 10 |

| Radiation penetration depth (in steel equivalent), mm | |

| - for steel | 350 |

| - for mineral oil | 3000 |

| Spatial resolution, mm | 5 |

| Density resolution, % | 1 |

LIST OF EQUIPMENT

Basic (minimal) set of customs inspection complexes consist of

- Linear electron accelerator

- X-ray beam collimation system

- Detector line

- Data transfer system

- Data processing and visualization system

- Transportation system of the examined object (EFASCAN)

- Transportation system of linac, detector line and X-ray beam collimation system (EFASCAN-2)

- Radiation, electrical and mechanical safety system

- Control system

- Cargo shipping documents input system

- Archiving system

| Major technical specifications of linear electron accelerator used in complexes | EFASCAN | EFASCAN-2 | EFASCAN-3 |

| Accelerator | UEL-10-D | UEL-10-D | |

| X-ray source energy, MeV | 9 | 6 | 10 |

| X-ray dose rate at 1 m from target, Gy·m2/min | 25-40 | 15 | 40 |

| Repetition rate, Hz | 150 | 150-300 | 300 |

| Focus spot diameter, mm | <2 | <2 | <2 |

Options to the EFASCAN complex

- Steresystem ...

- System with two accelerators and doubled set of equipment allows obtaining X-ray images of container in horizontal and vertical projections.

- System with dual energy of X-ray beam provides discrimination of groups of materials according to their average atomic number. Colored information on material of inspected cargo and distribution of integral absorption is visualized on screen of inspector’s workstation.

|

| Image of cargo container in material-color encoding |

Major advantages

- Continuous round-the-clock operation of customs checkpoint resulting in its higher throughput, efficiency and quality of inspection with lower expenditures;

- Obtaining most exhaustive real-time information on object under inspection;

- High-speed data processing and high quality of images ensured by applied software;

- Opportunity to compare the actual contents of inspected containers with the cargo declared in cargo manifest;

- Archiving the obtained data;

- Opportunity of scrupulous analysis of suspicious objects with no reduction of the complex throughput due to several available workstations;

Comparison with similar systems

Developed system of radioscopic examination is differed from analogous ones of famous firms (Heimann, Hi-Co-Scan, British Aerospace, Corrigan) by using of the specially elaborated effective mathematical software and hardware for data processing and visualization. The most impressive features are:

- Spatial super resolution achieved by using a syntetic point spread function;

- Глубокое подавление шумов методами непрерывного вейвлет-преобразования и кластерного анализа;

- Outstanding dynamic range of detector line (up to 3·10 5);

- Discrimination of groups of material according to atomic number (as option);

- Stereoscopic representation of examined objects (as option).